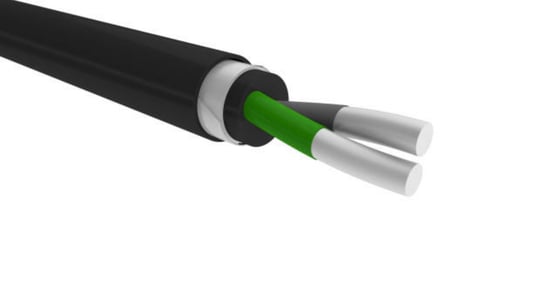

Understanding Underground Cable Joint IntegrityEnsuring the integrity of underground cable joints is essential for the efficient operation of any electrical system. These joints are the connection points where different cables are joined together, allowing for the seamless flow of electricity.Common Causes of Cable Joint FailureThere are several reasons why underground cable joints may fail, including environmental factors such as moisture ingress, temperature fluctuations, and ground movement. Poor installation techniques and lack of proper maintenance can also contribute to joint failures.Effects of Cable Joint FailuresWhen underground cable joints fail, it can lead to power outages, safety hazards, and costly repairs. In some cases, joint failures can even result in fires or explosions, posing a significant risk to both property and life.Importance of Regular InspectionsRegular inspections of underground cable joints are crucial to identify any potential issues before they escalate into larger problems. By detecting and addressing issues early on, you can prevent costly downtime and ensure the safety and reliability of your electrical system.Types of Cable Joint MaterialsThere are various materials used in underground cable joints, including heat-shrinkable materials, resin-filled joints, and cold shrink joints. Each type of material has its own set of advantages and is used based on the specific requirements of the application.Proper Installation TechniquesProper installation of underground cable joints is essential to ensure their long-term performance and reliability. This includes following manufacturer guidelines, using high-quality materials, and adhering to industry best practices.Importance of Testing and CertificationAfter installation, it is important to conduct testing to ensure that the underground cable joints meet industry standards for performance and safety. Certification by a reputable third-party organization can provide peace of mind and assurance of quality.Signs of Cable Joint DegradationThere are several signs that indicate underground cable joint degradation, such as overheating, discoloration, or visible damage to the insulation. If any of these signs are observed, immediate action should be taken to prevent further issues.Mitigation Strategies for Cable Joint IntegrityTo mitigate the risk of underground cable joint failures, it is important to implement preventive maintenance strategies, such as regular inspections, testing, and maintenance. Additionally, investing in high-quality materials and skilled labor can help enhance the longevity and performance of cable joints.ConclusionMaintaining the integrity of underground cable joints is essential for the safe and efficient operation of electrical systems. By understanding the common causes of joint failures, implementing proper installation techniques, conducting regular inspections, and investing in quality materials, you can ensure the reliability and safety of your underground cable joints.Quote Inquirycontact us