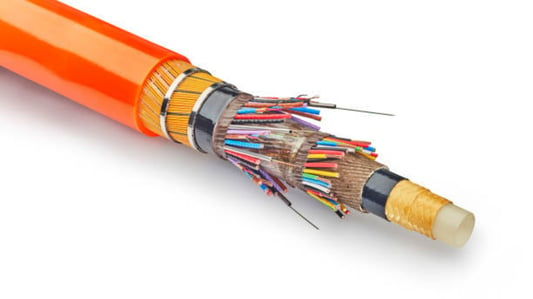

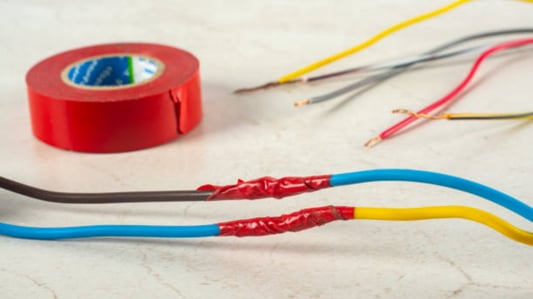

Introduction to Heat shrink cable headHeat shrink cable heads are specialized components designed to provide insulation, protection, and sealing for cable terminations. These heads utilize heat shrink technology, where a thermoplastic material shrinks tightly over the cable upon heating. This process results in enhanced durability, environmental protection, and electrical insulation, making heat shrink cable heads essential in various electrical and telecommunication installations.Materials Used in Heat Shrink Cable HeadsThe construction of heat shrink cable heads typically involves cross-linked polyolefin or similar polymers that contract when exposed to heat. Some designs integrate additional layers such as adhesive or metal shields to improve moisture resistance and electromagnetic interference shielding. These materials ensure the cable heads offer robust protection against mechanical stress, environmental exposure, and electrical hazards.Applications Across IndustriesHeat shrink cable heads find extensive applications in industries such as telecommunications, power distribution, and aerospace. They are crucial in protecting cable joints and connections in underground, underwater, and outdoor environments. The ability to withstand harsh weather conditions and chemical exposure makes heat shrink cable heads indispensable in industrial installations where reliability and safety are paramount.Types of Heat Shrink Cable HeadsVarious types of heat shrink cable heads are available depending on cable size, voltage rating, and environmental requirements. Common types include single-core and multi-core cable heads, indoor and outdoor versions, as well as those designed for low, medium, and high voltage applications. Selecting the appropriate type ensures optimum performance and compliance with industry standards.Advantages Over Traditional Cable Termination MethodsCompared to mechanical connectors or tape-insulated joints, heat shrink cable heads offer superior sealing, electrical insulation, and mechanical strength. The uniform shrinkage around the cable prevents moisture ingress, reduces corrosion, and enhances overall cable lifespan. Additionally, installation tends to be quicker and more efficient, reducing downtime during electrical repairs or upgrades.Installation Process ExplainedInstalling heat shrink cable heads involves several steps: stripping the cable insulation, inserting the cable into the heat shrink assembly, and applying heat evenly using a heat gun or oven. Proper heating ensures the material contracts tightly and the adhesive layers bond securely, creating a reliable, moisture-proof seal. Adequate training and adherence to manufacturer guidelines are essential to achieving optimal installation results.Environmental Resistance and DurabilityHeat shrink cable heads provide excellent resistance against UV radiation, water ingress, chemicals, and mechanical abrasion. This resistance is critical for cables exposed to outdoor environments, industrial pollutants, or marine conditions. Their durability helps maintain stable electrical performance and reduces the frequency of maintenance and replacement in critical infrastructure.Electrical Insulation and Safety BenefitsOne of the primary functions of a heat shrink cable head is to offer enhanced electrical insulation and prevent short circuits. By tightly conforming to the cable surface, the heat shrink material eliminates air gaps that can cause partial discharge. Furthermore, it protects personnel from accidental contact with live conductors, improving workplace safety.Customization and Compatibility OptionsManufacturers offer heat shrink cable heads in various sizes and customizable configurations to match specific cable diameters, voltages, and environmental conditions. Accessories such as adhesive liners, stress cones, and grounding components can be integrated. This flexibility allows heat shrink cable heads to be tailored for a wide range of electrical systems, from residential wiring to heavy industrial networks.Future Trends and InnovationsEmerging advancements in heat shrink cable head technology focus on improving material properties such as flame retardancy, enhanced thermal conductivity, and faster installation methods. Integration of smart sensors within cable heads for real-time monitoring of temperature and humidity is also a developing trend. These innovations aim to increase the reliability and intelligence of electrical networks while maintaining ease of installation.Quote Inquirycontact us