Introduction

Cable termination is a crucial process that ensures the seamless transfer of electricity from one device to another. When it comes to high voltage connections, 1kV Cold Shrink Cable Termination is one of the most important and reliable methods. In this article, we will explore the ins and outs of this process, including its benefits, installation process, and more.

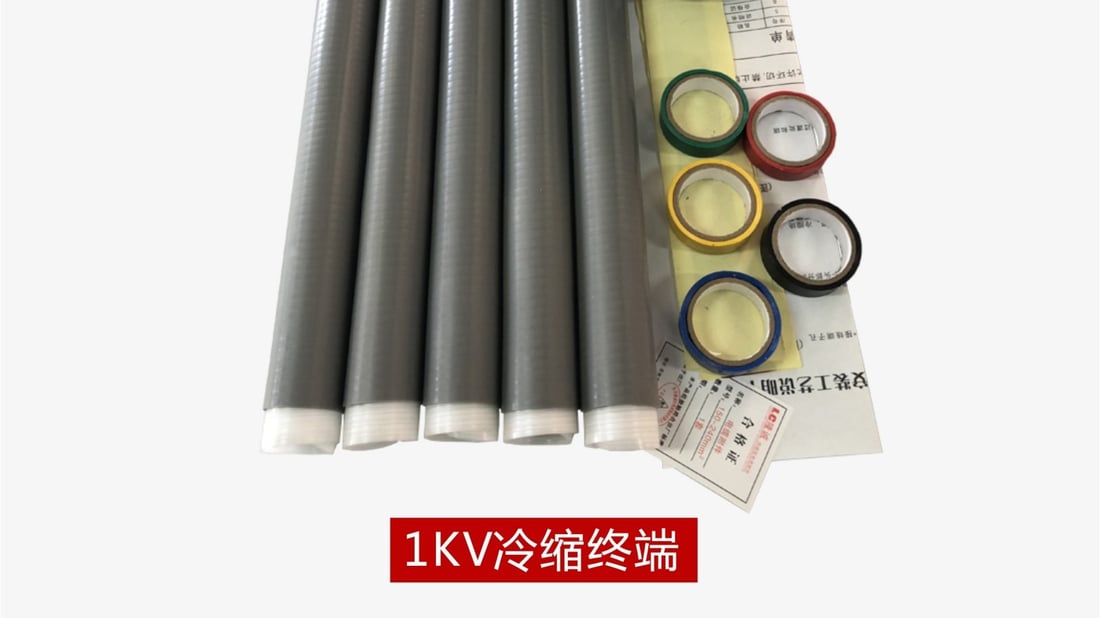

What is 1kV Cold Shrink Cable Termination?

Cold shrink cable termination is a sealing and insulation solution used to terminate medium and high voltage cable systems. The process involves applying pre-expanded, silicone rubber tubes over the cable ends that reduce the diameter of the tube and create a tight seal when stretched. The silicon rubber tubes shrink over time, creating a secure and air-tight seal that ensures excellent electrical performance and mechanical resistance. The 1kV Cold Shrink Cable Termination process is designed for voltages of up to 1kV.

The Benefits of 1kV Cold Shrink Cable Termination

1kV Cold Shrink Cable Termination offers several benefits over other cable terminations. Firstly, it is a cost-effective solution that is easy to install. Secondly, it provides excellent long-term reliability and sealing properties. Thirdly, this method offers superb insulation performance, which is critical for high voltage applications. Fourthly, it is highly resistant to weather and UV radiation, making it ideal for outdoor installations.

Installation Process of 1kV Cold Shrink Cable Termination

The installation process of 1kV Cold Shrink Cable Termination is simple and can be completed by a trained technician. The process involves the following steps:

- Clean and inspect the cable and accessory surfaces

- Prepare the cable ends and connector

- Slide the cold shrink tube over the cable end and position it correctly

- Expand the tubing using the conductor installation rod

- Cut the end of the exposed conductor, crimp and connect to the terminal lug

- Push the connector into place and apply silicone grease over the connector

- Clean and inspect the system after installation

Features of 1kV Cold Shrink Cable Termination

Some of the key features of 1kV Cold Shrink Cable Termination include:

- Excellent electrical and mechanical performance

- Easy to install and cost-effective solution

- Provides long-term reliability and sealing properties

- Excellent insulation performance

- Highly resistant to weather and UV radiation

- Aesthetically pleasing and unobtrusive

Use Cases for 1kV Cold Shrink Cable Termination

1kV Cold Shrink Cable Termination is used in various applications, ranging from power transmission to telecommunication cables. Some of the common use cases include:

- Indoor and outdoor distribution cables

- Power cables for the oil and gas industry

- Electricity transmission lines

- Offshore platforms and marine applications

- Coal and mining industry cables

Quality Standards for 1kV Cold Shrink Cable Termination

The quality standards for 1kV Cold Shrink Cable Termination are critical to ensure its reliability and safety. Some of the widely recognized standards for cable termination include:

- IEEE 48 – Standard for Test Procedures and Requirements for High-Voltage Alternating-Current Cable Terminations

- IEEE 404 – Standard for Test Procedures and Requirements for Medium-Voltage Cable Terminations

- IEC 60228 – Conductors of insulated cables

- IEC 60156 – Insulating liquids - Determination of the breakdown voltage at power frequency

In Conclusion

1kV Cold Shrink Cable Termination is a reliable and cost-effective solution for high voltage connections. Its key features like excellent electrical performance, easy installation, and high resistance to weather and UV radiation make it a preferred method for various applications. With proper installation and adherence to quality standards, 1kV Cold Shrink Cable Termination can provide reliable performance for many years.