What is Cold Shrink Tubing?

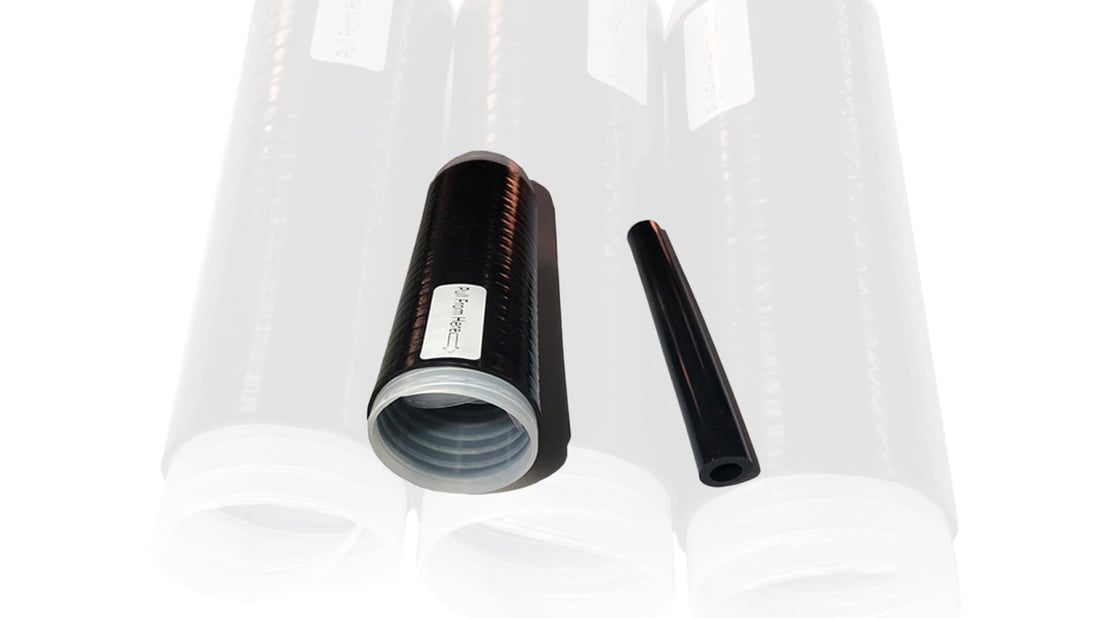

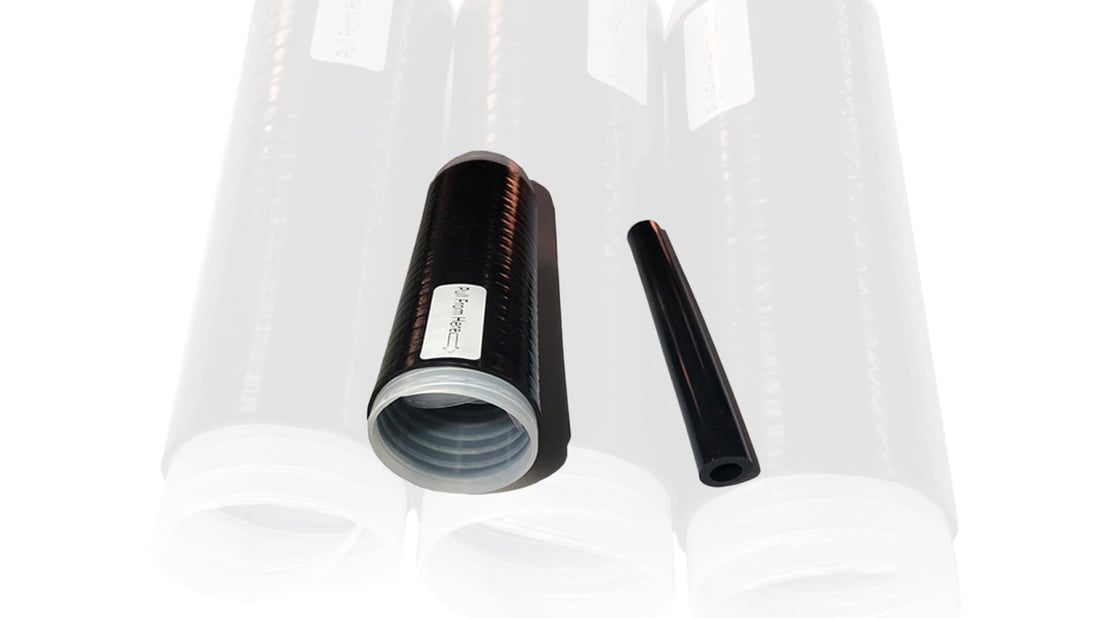

Cold shrink tubing is a type of heat shrink tubing that does not require heat to shrink. It is made of a rubber material that shrinks when the removable core is taken out. Cold shrink tubing is commonly used in electrical applications to provide insulation and protect connections.

Advantages of Using Cold Shrink Tubing

One of the main advantages of cold shrink tubing is its ease of installation. It is a quick and convenient solution for insulating wires and cables without the need for heat guns or other tools. Cold shrink tubing also provides a tight seal that is resistant to moisture, making it ideal for outdoor and harsh environments.

Cold shrink tubing comes in a variety of sizes to accommodate different cable diameters. Sizes typically range from a few millimeters to several inches in diameter. It is important to choose the right size of cold shrink tubing to ensure a proper fit and secure seal.

Factors to Consider When Choosing Cold Shrink Tubing Sizes

When selecting the size of cold shrink tubing, consider the diameter of the cable or wire you need to insulate. Measure the cable diameter accurately to determine the appropriate size of tubing needed. It is also important to consider the length of the tubing to ensure complete coverage.

Installation Process for Cold Shrink Tubing

To install cold shrink tubing, simply slide the tubing over the cable or wire and position it in place. Remove the core or insert to allow the tubing to shrink and conform to the shape of the cable. Ensure that the tubing is securely in place and covers the entire length of the area being insulated.

Common Applications of Cold Shrink Tubing Sizes

Cold shrink tubing sizes are commonly used in telecommunications, power distribution, and automotive industries. They are ideal for insulating electrical connections, splices, and terminations. Cold shrink tubing provides protection against moisture, corrosion, and environmental factors.

Benefits of Using the Correct Cold Shrink Tubing Size

Using the correct size of cold shrink tubing ensures a proper and secure fit, which helps to prevent moisture ingress and maintain the integrity of the connection. Proper sizing also ensures optimal electrical insulation and protection.

Choosing the Right Material for Cold Shrink Tubing

Cold shrink tubing is available in various materials such as silicone, EPDM rubber, and butyl rubber. The material chosen should be compatible with the application and environment. Silicone cold shrink tubing is suitable for high temperature and harsh environments, while EPDM rubber offers good electrical insulation properties.

Storage and Handling of Cold Shrink Tubing Sizes

To maintain the effectiveness of cold shrink tubing, store it in a cool, dry place away from direct sunlight and heat sources. Avoid bending or stretching the tubing during storage to prevent damage. Handle the tubing with care to avoid tears or punctures.

Maintenance and Replacement of Cold Shrink Tubing

Regular inspection of cold shrink tubing is recommended to check for any signs of wear, damage, or degradation. If any issues are found, it is important to replace the tubing promptly to ensure continued protection and insulation.

Quote Inquiry

contact us