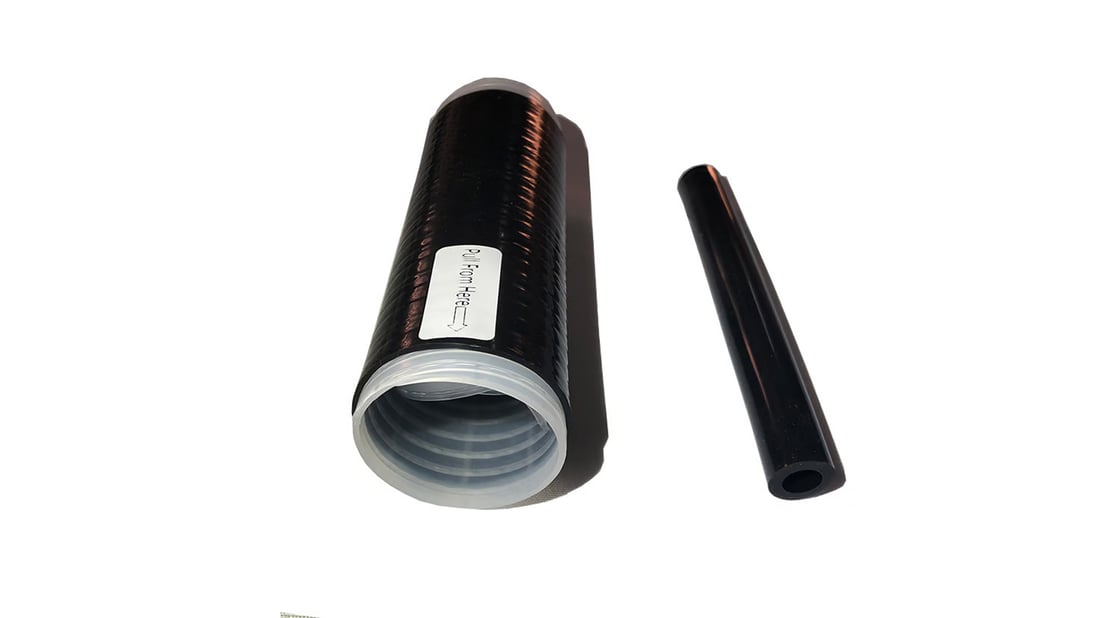

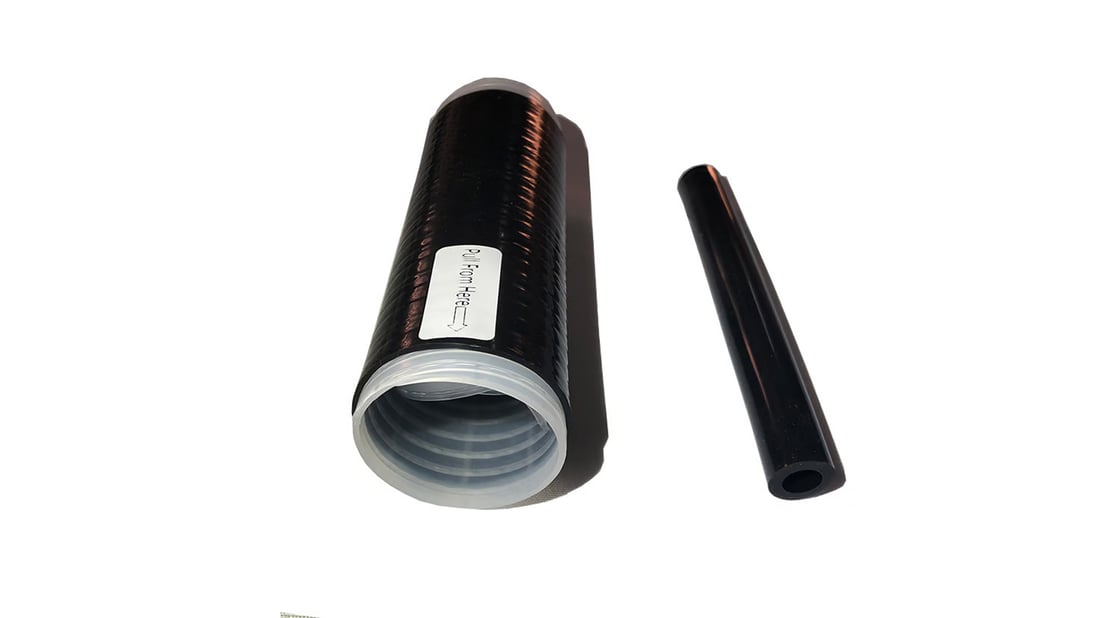

Cold shrink sleeves are a type of cable accessory that provides insulation, sealing, and protection for electrical cables. They are made of rubber or silicone material that contracts when a removable core is extracted, providing a tight fit around the cable.

Benefits of Cold Shrink Sleeves

Cold shrink sleeves offer several advantages over other types of cable accessories. They are easy to install, requiring no heat or tools. They provide excellent protection against moisture, chemicals, and extreme temperatures. They also offer superior flexibility and durability, ensuring long-lasting performance.

Applications of Cold Shrink Sleeves

Cold shrink sleeves are commonly used in various industries, including telecommunications, power distribution, and automotive. They are ideal for sealing and insulating cable connections, splices, and terminations. They can also be used for environmental sealing and mechanical protection in outdoor or harsh environments.

Choosing the Right Cold Shrink Sleeve

When selecting a cold shrink sleeve, it is important to consider factors such as cable size, operating temperature, and environmental conditions. It is also crucial to ensure the sleeve meets industry standards for electrical insulation and protection. Consulting with a professional can help determine the best sleeve for your specific application.

Installation Process of Cold Shrink Sleeves

The installation of cold shrink sleeves is straightforward and quick. Simply slide the sleeve onto the cable, position it over the connection or termination, and remove the core to shrink the sleeve into place. The elasticity of the material ensures a secure and tight fit without the need for additional tools or heat.

Maintenance of Cold Shrink Sleeves

Cold shrink sleeves require minimal maintenance once installed properly. It is important to inspect the sleeves periodically for any signs of damage, wear, or degradation. If any issues are detected, the sleeves should be replaced promptly to ensure continued protection and performance.

Cost-Efficiency of Cold Shrink Sleeves

While cold shrink sleeves may have a higher initial cost compared to other cable accessories, they offer long-term cost savings. Their durability and reliability reduce the need for frequent replacements or repairs, ultimately lowering maintenance costs and downtime in the long run.

Environmental Impact of Cold Shrink Sleeves

Cold shrink sleeves are designed to be environmentally friendly, as they do not require any heat sources or chemicals during installation. Their durable material also ensures a longer lifespan, reducing waste and the need for disposal. This makes them a sustainable choice for cable protection.

Advancements in Cold Shrink Sleeve Technology

As technology continues to evolve, so do cold shrink sleeves. Manufacturers are constantly innovating to improve the performance, durability, and versatility of these cable accessories. New materials and designs are being developed to meet the changing needs of the industry.

Conclusion

Cold shrink sleeves are a versatile and reliable solution for insulating, sealing, and protecting electrical cables. With their easy installation, durability, and cost-efficiency, they are a popular choice for various industries. By understanding their benefits, applications, and advancements in technology, users can make informed decisions when selecting cold shrink sleeves for their cable needs.

Quote Inquiry

contact us