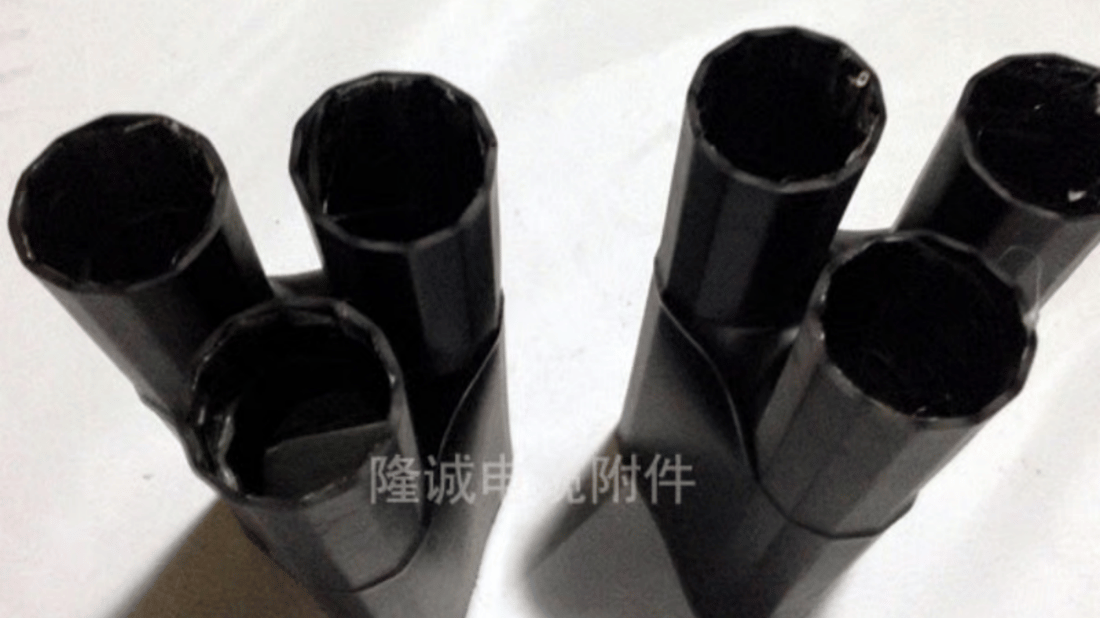

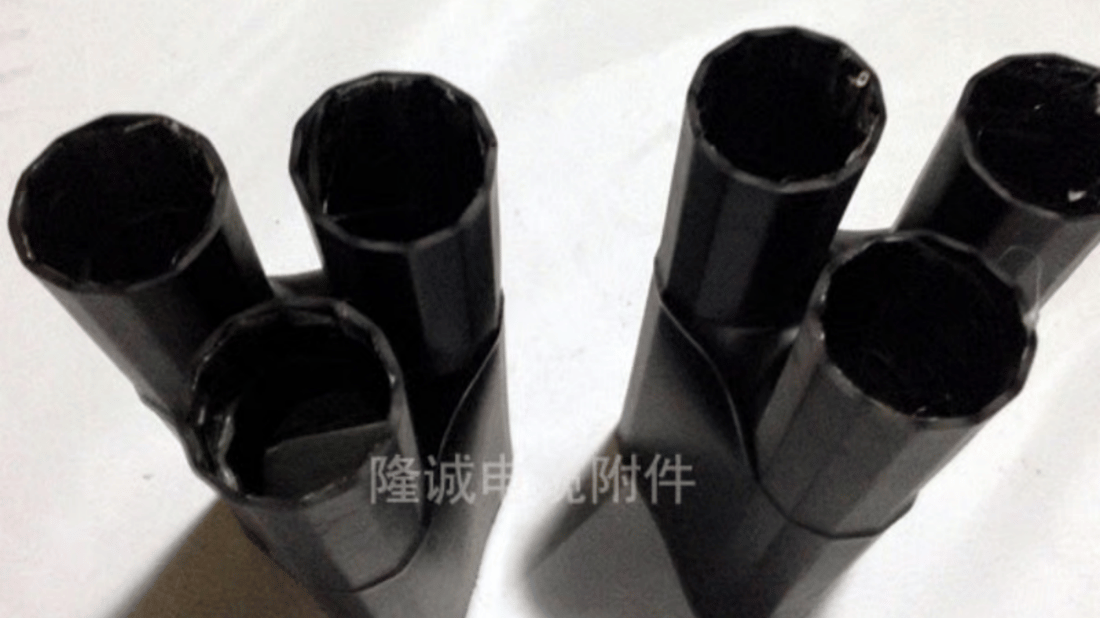

Heat shrink finger cots are specialized protective coverings designed to fit snugly over individual fingers. Utilizing heat-activated materials, these cots shrink to form a tightly sealed barrier, offering enhanced protection against contaminants, moisture, and mechanical hazards. Widely used in electronics, medical, and industrial sectors, heat shrink finger cots are essential for precision work where finger coverage and tactile sensitivity are required simultaneously.

Material Composition and Heat Shrinking Technology

Typically made from polyolefin or similar heat-sensitive polymers, heat shrink finger cots undergo a transformation when exposed to controlled heat sources. The material contracts uniformly around the finger, creating a seamless fit. This unique property provides a secure barrier that adapts to various finger sizes, ensuring comfort without impeding dexterity. The polymer mix also offers resistance to chemicals and abrasion, expanding their usability across multiple industries.

Applications in Electronics Manufacturing

In electronics production and repair, heat shrink finger cots protect delicate components and prevent contamination from oils, sweat, or static discharge. Their snug fit allows users to handle sensitive circuits with precision while avoiding damage from dust or electrostatic buildup. Additionally, the insulating qualities of some heat shrink finger cots help minimize static interference during assembly or testing procedures.

Medical and Laboratory Usage

Healthcare professionals and laboratory technicians utilize heat shrink finger cots to maintain sterile environments and reduce cross-contamination risk. These cots serve as finger protectors during examinations, sample handling, or while dealing with hazardous materials. Because they conform tightly, they do not impede finger movement, making tasks like specimen collection and medical device handling more efficient and hygienic.

Protection in Industrial and Mechanical Settings

In industrial environments, heat shrink finger cots protect against cuts, burns, and chemical exposure during assembly, inspection, or maintenance work. Their heat-shrink capability ensures the cot stays secure even in dynamic work situations, unlike traditional finger covers that may slip. They also serve as valuable safeguards where precision and finger protection are critical, offering resistance against oils, solvents, and mechanical abrasion.

Customization and Sizing Options

Heat shrink finger cots come in various sizes and thicknesses, catering to different finger diameters and protective needs. Customization options include color coding, material hardness, and thickness variations to suit specific industry requirements. This flexibility makes it easier for users to select optimal protection based on task sensitivity and environmental factors, enhancing workplace safety while preserving user comfort.

Advantages Over Traditional Finger Cots

Unlike standard finger cots, heat shrink varieties provide a more durable and secure fit due to their heat-activated shrinking feature. This eliminates concerns about slipping or loose coverage during critical operations. The enhanced adaptability enables longer wear times and improved protection against moisture, contaminants, and mechanical damage, ultimately extending the finger cot’s functional lifespan.

Environmental and Safety Considerations

Many heat shrink finger cots are manufactured with eco-friendly materials that comply with safety and environmental standards. Their usage reduces the need for disposable gloves in certain tasks, minimizing waste. Additionally, proper disposal and recycling of these cots can further decrease environmental impact, making heat shrink finger cots a sustainable choice for companies focused on reducing their ecological footprint.

Cost-effectiveness and Efficiency in the Workplace

Heat shrink finger cots combine affordability with high performance, making them an economical choice for industries requiring frequent finger protection. Their durability reduces replacement frequency, lowering operational costs. Furthermore, their ease of application through simple heat treatment enhances workflow efficiency, saving time during preparation phases and allowing quicker transitions between tasks.

Future Trends and Innovations

As materials science advances, heat shrink finger cots are expected to evolve with enhanced antimicrobial coatings, improved tactile sensitivity, and greater environmental compatibility. Integration with smart textiles or sensor technology may offer added functionality such as biometric monitoring or contamination detection. These innovations will likely broaden the applications of heat shrink finger cots, solidifying their role in precision industries moving forward.

Conclusion: Choosing the Right Heat Shrink Finger Cot

Selecting the appropriate heat shrink finger cot requires consideration of material properties, size, application environment, and protection level needed. Understanding these aspects ensures optimized performance, safety, and comfort. With benefits spanning multiple sectors and continuous technological progress, heat shrink finger cots remain a significant tool for finger protection, precision handling, and contamination control in modern industries.

Quote Inquiry

contact us