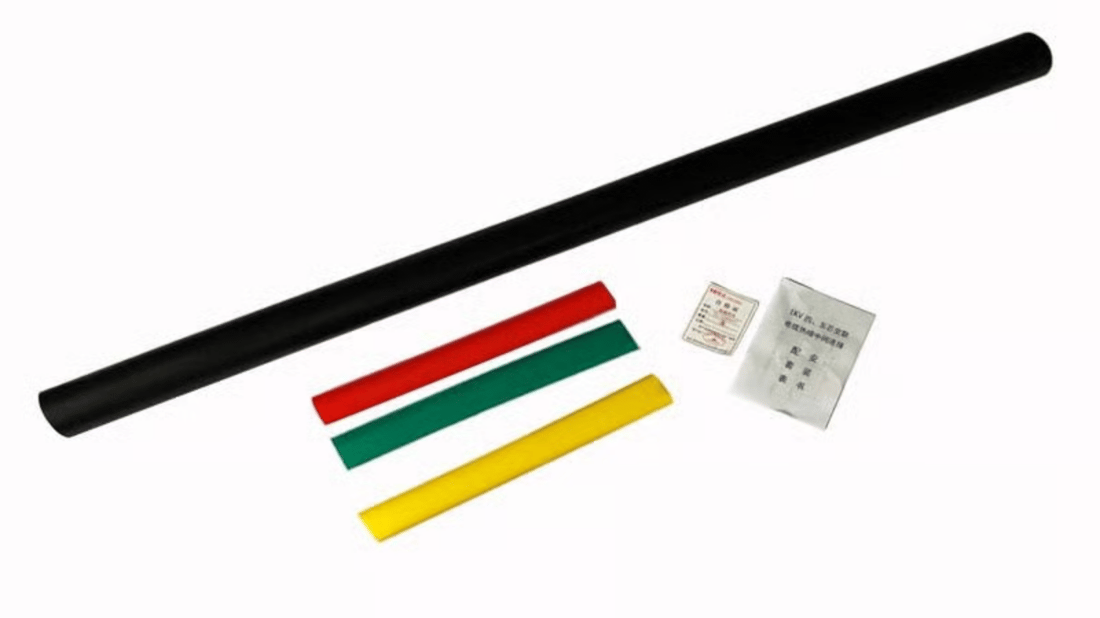

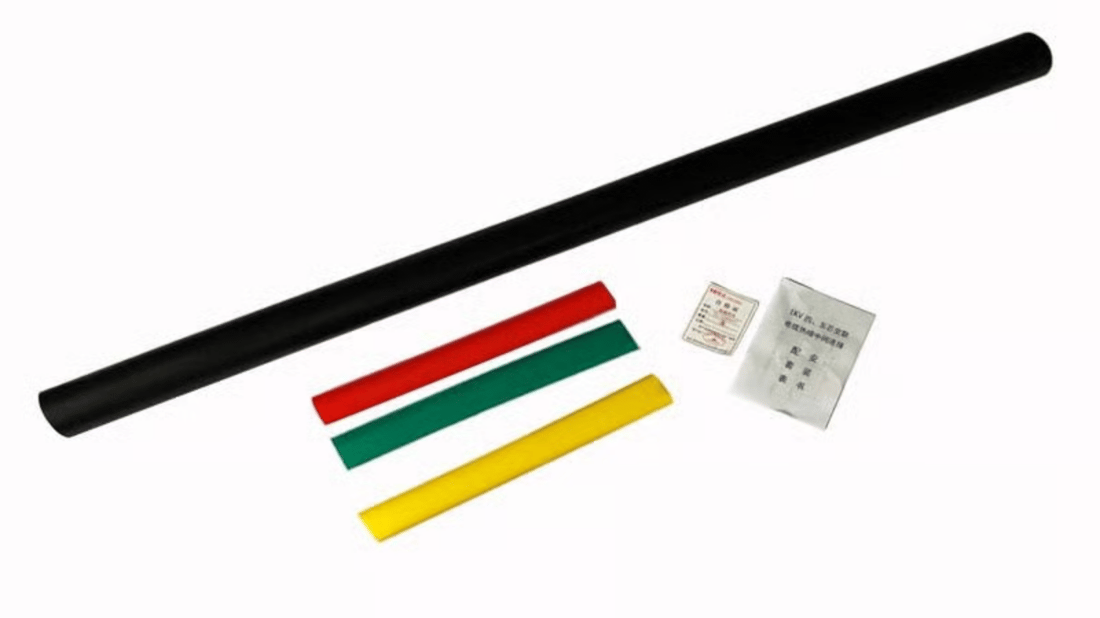

A five-core heat shrink intermediate connection is a critical component used in electrical wiring and cabling systems. Designed to seamlessly connect and protect five-core cables, these connections rely on heat shrink technology to provide robust insulation, moisture resistance, and mechanical protection. This type of connection is essential in environments where durability and safety are paramount.

The Structure and Composition of Five-Core Heat Shrink Connections

The five-core heat shrink intermediate connection comprises multiple insulated cores bundled together. Each core corresponds to individual conductors, typically including live, neutral, earth, and two additional lines depending on the application. The outer heat shrink sleeve, often made of polyolefin, shrinks when heated, forming a tight seal around the connection, preventing ingress of dust, water, and other contaminants.

Applications in Electrical Wiring and Power Distribution

These connections find extensive use in industrial, commercial, and residential power distribution setups. They are crucial for intermediate connections where five-core cables must be extended or joined without compromising electrical continuity and insulation integrity. Applications include lighting circuits, motor connections, and control wiring, ensuring reliable performance and reduced maintenance.

Advantages of Using Heat Shrink Technology

Heat shrink technology offers several advantages over conventional insulating methods like tape or cold-applied compounds. Five-core heat shrink intermediate connections provide uniform pressure around conductors, enhancing mechanical strength and electrical insulation. They also create a moisture-proof barrier, preventing corrosion and facilitating longer service life of joints.

Installation Process and Best Practices

Installing a five-core heat shrink intermediate connection requires careful stripping of cable insulation, proper crimping or soldering of conductors, and precise application of the heat shrink sleeve. The sleeve is heated using a heat gun or specialized equipment until it shrinks uniformly, ensuring a snug fit and reliable protection. Adhering to manufacturer guidelines guarantees optimal performance and safety.

Material Choices and Their Impact on Performance

The materials used in five-core heat shrink intermediate connections influence their electrical, thermal, and mechanical properties. Polyolefin is the most common material due to its excellent shrink ratio and resistance to environmental stress. Some variants include inner adhesive linings that melt upon heating, enhancing seal integrity and adhesion to cable surfaces for improved protection.

Environmental and Safety Considerations

Five-core heat shrink intermediate connections contribute significantly to safety in electrical installations by preventing short circuits and electrical faults caused by moisture and physical damage. Their design meets various international safety standards, ensuring compliance in critical applications. Additionally, the materials are chosen for fire retardancy and chemical resistance, enhancing overall installation safety.

Common Challenges and Solutions in Implementation

While effective, using five-core heat shrink intermediate connections can present challenges such as uneven heating, improper sealing, or compatibility issues with cable types. These problems can lead to weak insulation or mechanical failure. To mitigate these risks, proper training, use of recommended tools, and thorough inspection during and after installation are vital.

Comparison with Alternative Connection Methods

Compared to mechanical connectors, soldered joints, or cold-applied compounds, five-core heat shrink intermediate connections provide superior sealing and durability. While mechanical connectors may offer quicker installation, they do not necessarily protect against environmental hazards as effectively. Heat shrink connections balance ease of use with long-term reliability, making them a preferred choice in demanding settings.

Future Trends and Innovations in Heat Shrink Technology

Advancements in heat shrink technology continue to enhance the functionality of five-core intermediate connections. Innovations include improved adhesive formulations for better sealing, reduced shrink temperatures for sensitive applications, and integration with smart materials for fault detection. As electrical systems become more complex, these connections will evolve to meet stricter performance and safety standards.

Quote Inquiry

contact us