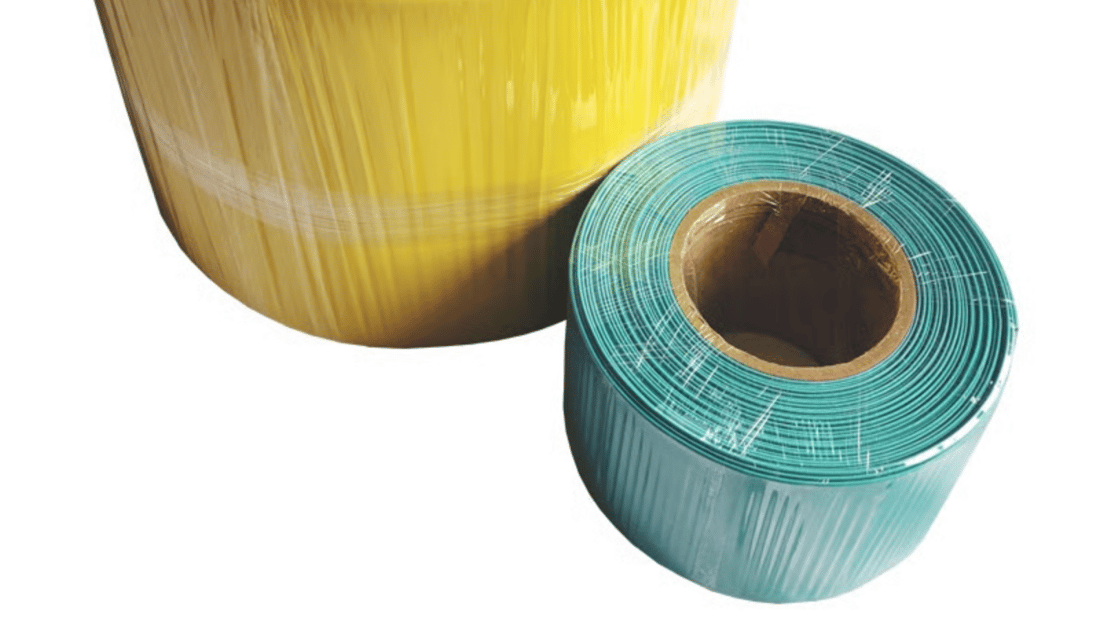

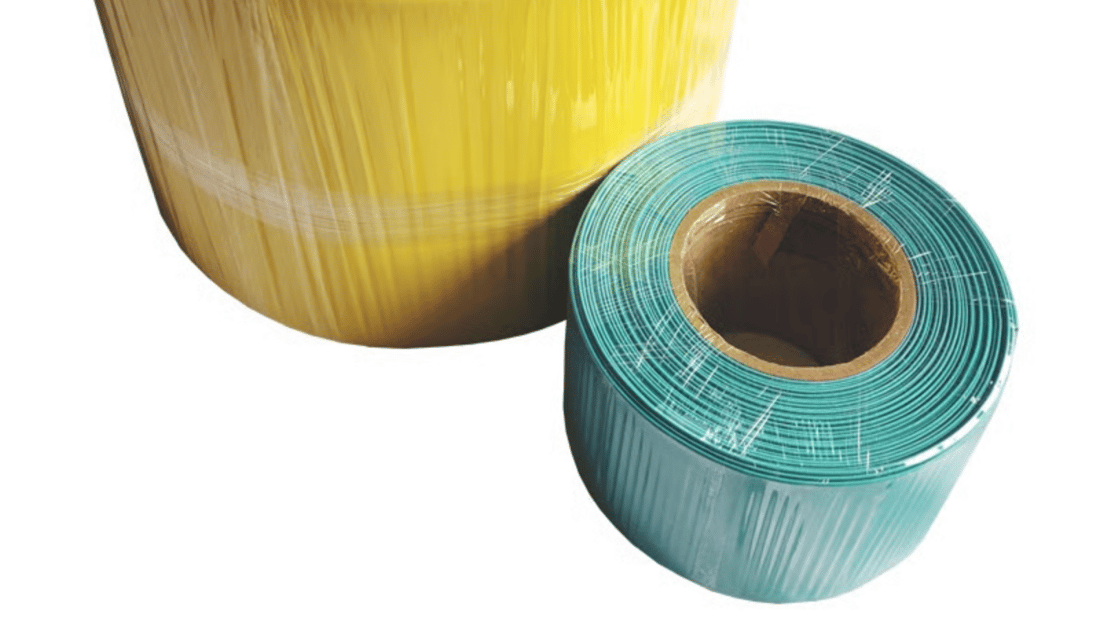

The 10KV heat shrink pipe is a specialized insulating accessory designed for medium-voltage cable joints and terminations. It is engineered to provide robust electrical insulation and environmental protection for cables operating at 10,000 volts (10KV). Manufactured using cross-linked polyolefin materials, this heat shrink pipe contracts when heated to create a tight, protective seal around cable connections, improving durability and reliability in electrical systems.

Material Composition and Manufacturing Process

The typical 10KV heat shrink pipe is made from high-quality, cross-linked polyethylene or polyolefin compounds, selected for their excellent electrical insulation, mechanical strength, and chemical resistance. The manufacturing involves extrusion of the polymer into a tubular shape followed by cross-linking through radiation or chemical processes to enhance thermal and mechanical properties. This allows the pipe to return to its original diameter securely after heat application, ensuring effective protection.

Electrical Insulation Properties

One of the critical features of the 10KV heat shrink pipe is its superior electrical insulation capability. It withstands high voltage stresses without breakdown, effectively preventing short circuits, leakage currents, and electrical failures. The pipe's dielectric strength supports safe operation within the 10KV range, making it a preferred choice for cable insulation in demanding electrical environments.

Thermal Performance and Heat Resistance

Designed to endure thermal stresses, the 10KV heat shrink pipe demonstrates excellent heat resistance, often operating efficiently in temperature ranges from -55°C to +125°C. This ability to withstand temperature fluctuations without deformation or loss of electrical performance makes it ideal for outdoor and industrial applications where cables may experience harsh conditions.

Mechanical Protection and Environmental Resistance

Beyond electrical insulation, the 10KV heat shrink pipe offers robust mechanical protection against abrasion, impact, and bending stresses. Its dense, cross-linked structure also provides resistance to moisture, chemicals, UV radiation, and corrosion. This ensures enhanced longevity of cable joints exposed to outdoor environments or aggressive industrial areas.

Installation Process and Ease of Use

Installation of the 10KV heat shrink pipe is straightforward, requiring only a hot air gun or similar heating tool. When heated, the pipe shrinks uniformly, conforming tightly to the cable joint or termination, eliminating air pockets and ensuring a waterproof seal. This ease of application reduces labor time and complexity, enabling quicker and more reliable cable repairs or installations.

Applications in Power Distribution and Industrial Sectors

10KV heat shrink pipes are widely used in medium-voltage power distribution networks, including overhead and underground cable systems. They are also prominent in industrial installations such as manufacturing plants, substations, and renewable energy grids. Their ability to provide safe, dependable insulation makes them indispensable in maintaining uninterrupted power delivery.

Compliance with Industry Standards and Certifications

Quality assurance for 10KV heat shrink pipe includes adherence to international standards like IEC 60684, IEEE, and UL specifications. These certifications verify electrical, mechanical, and environmental performance criteria, guaranteeing that products meet safety and reliability requirements for medium-voltage applications. Choosing certified products ensures compliance with regulatory frameworks and reduces operational risks.

Comparison with Alternative Insulation Methods

When compared to traditional electrical tapes, liquid insulation, or cold-shrink tubing, the 10KV heat shrink pipe excels in providing superior mechanical strength, permanent sealing, and thermal stability. Unlike tapes that may deteriorate or become loose over time, heat shrink pipes offer long-term protection with minimal maintenance. This makes it a cost-effective and trustworthy solution for medium-voltage cable insulation.

Future Trends and Innovations in Heat Shrink Technologies

Advancements in material science are driving innovations in 10KV heat shrink pipe design, including enhanced flame retardancy, faster shrinking times, and improved environmental sustainability. Emerging applications increasingly demand heat shrink products that can withstand higher temperatures and harsher environments. The integration of smart materials capable of self-monitoring or self-healing is expected to shape the next generation of heat shrink insulation solutions.

Quote Inquiry

contact us